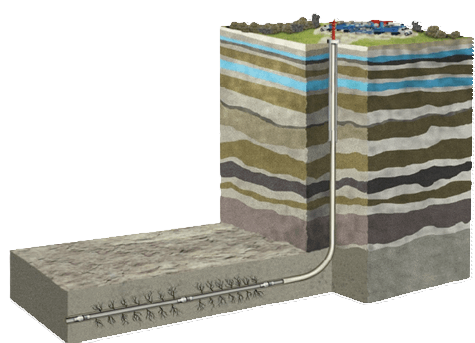

Acid fracturing is a vital technique in the oil and gas industry, employed to enhance well productivity by improving reservoir permeability. This method involves injecting acid at high pressure into the well, creating fractures in the rock formations and allowing for better flow of hydrocarbons. Here, we explore the core equipment used in acid fracturing and the practical applications of acid fracturing hoses.

Core Equipment in Frac Hose Acid Fracturing

1.High-Pressure Pumps

High-pressure pumps are the backbone of acid fracturing operations. They inject acid into the reservoir at pressures high enough to fracture the rock. These pumps need to be robust and reliable, capable of handling the corrosive nature of the acid while delivering consistent pressure.

2.Mixing Units

Mixing units are essential for preparing the acid solution on-site. These units blend the acid with various additives to create the desired fracturing fluid. The mixture must be precise to ensure the effectiveness and safety of the fracturing process.

3.Acid Storage Tanks

Storage tanks are used to hold large volumes of acid prior to and during the fracturing operation. These tanks are typically made from materials resistant to acid corrosion, such as fiberglass or specially coated steel, ensuring safe storage and handling.

4.Fracturing Lines and Manifolds

Fracturing lines and manifolds connect the surface equipment to the wellbore. These lines must withstand high pressures and the corrosive nature of the acid. They are designed to facilitate the smooth and safe transfer of the fracturing fluid to the target zones within the well.

5.Data Vans

Data vans are mobile control centers equipped with monitoring and control systems. They provide real-time data on pressure, flow rates, and other critical parameters, allowing engineers to make informed decisions during the fracturing process.

Applications of Acid Fracturing Hoses

Acid fracturing hoses play a crucial role in the safe and efficient delivery of acid to the wellbore. These hoses are designed to handle high pressures and the corrosive properties of the acid, making them indispensable in acid fracturing operations. Their applications include:

1.Acid Delivery

The primary use of acid fracturing hoses is to transport acid from storage tanks to the high-pressure pumps. These hoses need to be flexible yet durable, capable of withstanding the harsh conditions of the fracturing site.

2.Safety and Maintenance

Acid fracturing hoses are designed for easy inspection and maintenance. Regular checks and timely replacements are essential to prevent leaks and ensure the integrity of the fracturing operation. The materials used in these hoses are chosen for their resistance to acid corrosion, extending their operational life and reliability.

Conclusion

Acid fracturing is a sophisticated process that requires specialized equipment and materials to ensure its success. High-pressure pumps, mixing units, storage tanks, fracturing lines, and data vans form the backbone of this operation. Acid fracturing hoses, with their ability to handle high pressures and corrosive fluids, are critical for the safe and efficient delivery of acid to the wellbore. As technology advances, the equipment and techniques used in acid fracturing continue to evolve, enhancing the efficiency and safety of oil and gas extraction.